- PLC automatic control with manual operating screen , make sure the material evenly feeding during entire production line.

- Compact structure, reasonable layout, stable performance, Low noise.

- The crushing and grinding process equipped with a circulating water cooling machine, which avoid the plastic melting or discoloring because of the high temperature after long operation of the equipment.

- Physical crushing, grinding and electrostatic separation method to sort the aluminum and plastic. It is environmentally and friendly separation method which replaced the original chemical pharmacy aluminum-plastic separation.

- The entire production line is equipped with pulse dust collector, thus purifying the work space.

- The highest separating rate of aluminum and plastic can reach more than 99.9%.

- Equipment can be customized according to customers' capacity requirement.

| Model | Power (kw) | separating rate (%) | Dust Collection efficiency (%) | Output (kg/h) | Overall dimension (mm) | Weight (kg) |

| APS-300 | 70 | ≥99% | ≥99.5% | 200-300 | 7500*6000*4200 | 6500 |

| APS-600 | 115 | 500-600 | 9500*7500*4200 | 7800 | ||

| APS-800 | 215 | 700-800 | 11500*8000*4200 | 12800 |

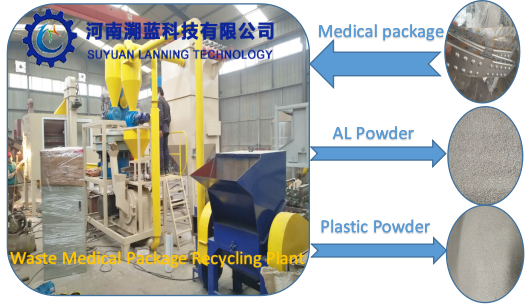

Raw waste:

Final Products: